Filtration is a core process in many laboratory workflows, from microbiological testing to sample preparation for analytical techniques such as HPLC. Selecting the right system can have a major impact on efficiency, accuracy, and overall sample quality. At Apex Scientific, we supply the premium Wiggens filtration systems, designed for precision, chemical compatibility, and durability in demanding lab environments.

Whether you are filtering water samples, culture media, or solvents, asking the right questions at the start ensures you get a setup that meets your performance and budget requirements.

Determining Filtration Capacity

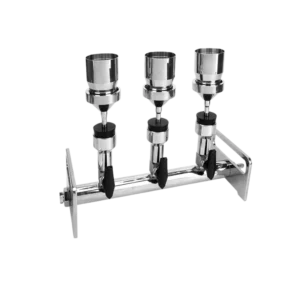

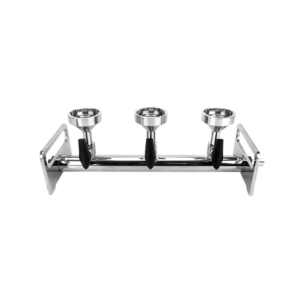

One of the first considerations is how many filtration units you need to operate simultaneously. Wiggens offers single-place, three-place, and six-place systems, allowing you to process anywhere from a single sample to multiple samples in parallel. Multi-place systems are ideal for high-throughput labs, while single-place units suit smaller workloads or specialised applications.

Selecting the Right Filter Cup Size

Filter cup size directly affects how much sample you can process in one run. Common sizes include 250 mL, 500 mL, and 1 L. The choice depends on your sample volume, but it also needs to match your membrane diameter — typically 25 mm, 47 mm, or 90 mm — to ensure an effective seal and filtration rate.

Material Compatibility for Chemicals and Solvents

Different applications require different filter cup materials. Wiggens systems are available in glass, stainless steel, polypropylene, and PTFE-coated options.

- Glass is ideal for general microbiology and water testing.

- Stainless steel offers strength and longevity for more rugged use.

- Polypropylene provides cost-effectiveness and chemical resistance.

- PTFE coatings handle aggressive solvents and highly corrosive solutions.

If you are working with solvents, confirming compatibility is essential to prevent degradation or contamination.

Waste Management and Collection Bottles

A waste collection bottle helps maintain a clean and safe work environment, particularly in high-throughput labs. Wiggens offers bottles in various capacities, with autoclavable options for sterile workflows. Selecting the correct volume ensures you avoid frequent emptying while preventing overflow during extended runs.

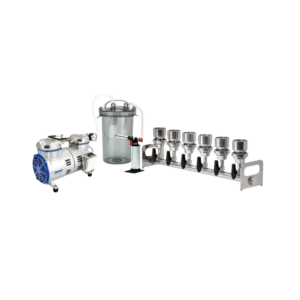

Vacuum Pump Requirements

Filtration speed depends largely on the vacuum source. If you do not have an existing pump, Wiggens systems can be paired with high-quality laboratory vacuum pumps that provide the necessary flow rate and ultimate vacuum for your application. If you already have a pump, check its specifications to ensure it matches your desired throughput and compatibility.

Matching Filtration Speed to Your Workflow

Throughput needs vary significantly. Environmental testing labs may require fast processing of many samples, while research labs may prioritise gentle filtration to preserve sample integrity. Wiggens systems are engineered to accommodate both ends of the spectrum, giving you control over speed without compromising results.

Application-Specific Considerations

The ideal filtration setup can differ greatly between applications:

- Microbiology: Sterile filtration of culture media or water samples.

- HPLC sample prep: Removal of particulates to protect analytical columns.

- Environmental testing: Processing water and soil extracts for microbial or chemical analysis.

- Particle analysis: Capturing particulates on membranes for further study.

Knowing your application helps select the correct membrane type, pore size, and any additional accessories.

Accessories and Upgrades

From additional filter cups to spare membranes, tubing, and adaptors, having the right accessories keeps your system running efficiently. Wiggens offers a full range of add-ons to extend system versatility and lifespan.

Why Choose Wiggens Filtration Systems from Apex Scientific?

With decades of experience in laboratory equipment supply, Apex Scientific ensures you receive expert advice, tailored recommendations, and after-sales support. As the official distributor of Wiggens in South Africa, we provide:

- Access to the full Wiggens filtration product line.

- Guidance on chemical compatibility and performance requirements.

- Integrated solutions with matching vacuum pumps and waste handling systems.

Talk to Our Specialists

Selecting the right filtration system is more than just choosing a cup size or pump. It’s about building a setup that works efficiently, lasts for years, and delivers reproducible results.

Contact Apex Scientific today to discuss your application and explore the Wiggens filtration systems that will best fit your needs.

Recommended products

Funnel Filtration Sets

Bench-Top Vacuum Filtration Systems

Filtration Manifolds – BioVac 340/640 Series

Multi Position Filtration Manifold Sets with Vacuum

Multi-Position Filtration Manifolds – BioVac 320/620

Multi-Position Filtration Manifolds – BioVac 350/650 Series

Multi-Position Filtration Manifolds – BioVac 360/660 Series

Multi-Position Manifolds – BioVac 330/630 Series

Portable Vacuum Filtration Systems