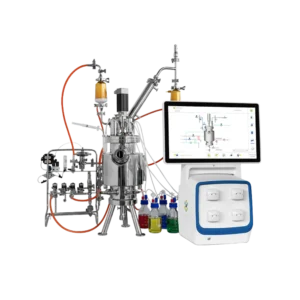

The bioreactor or fermenter by Solaris Biotech is designed for precise control and dependable results. Moreover, this single benchtop unit features a 2 L autoclavable glass vessel with a 3:1 height-to-diameter ratio. Therefore, it supports a wide range of fermentation and cultivation processes. Scientists can run single experiments or operate up to 24 systems in parallel, which makes research scalable across South Africa.

Key Features and Design

This compact stirred system uses a single-wall borosilicate glass vessel combined with a heating blanket and cooling finger. As a result, thermoregulation remains accurate and consistent. The bioreactor or fermenter works for microbial as well as cell culture applications. In addition, options include Toro or sintered spargers, Rushton or marine impellers, and integrated baffles. Measurements for temperature, pH, dissolved oxygen, and stirring speed are included, while a brushless motor ensures smooth mixing with precision down to 1 RPM.

Intelligent Control and Connectivity

Furthermore, the ONE offers advanced control through the SCADA Leonardo software. Consequently, scientists can automate fermentation processes and record data continuously. Built-in Wi-Fi also simplifies remote monitoring and improves integration with existing laboratory equipment. In addition, four fixed-speed Watson Marlow peristaltic pumps provide reliable media and reagent delivery.

Applications and Benefits

In summary, the Solaris Biotech ONE supports laboratory research, education, process development, and both scale-up and scale-down studies. Because it is autoclavable, the system maintains sterility and allows easy maintenance.

Learn more about integrating the Solaris Biotech ONE into your workflow by visiting the Apex Scientific Insights page, or contact our team today to explore this innovative laboratory equipment.