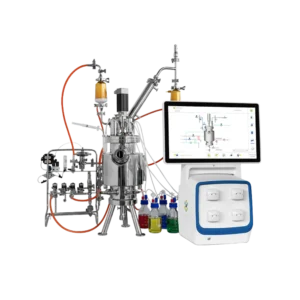

The gas analyzer for bioreactors from Solaris Biotech provides precise, real-time monitoring of O₂ and CO₂ for microbial and cell culture applications. Specifically, it is designed for laboratory equipment setups in South Africa, and the Metis system supports multi-channel operation, allowing connection to up to eight fermenters or bioreactors simultaneously. Furthermore, supplied with a dedicated PC and touchscreen HMI, it enables accurate parameter monitoring and control while providing continuous graphical representation of gas concentrations, oxygen uptake rate (OUR), carbon dioxide evolution rate (CER), and respiratory quotient (RQ).

Advanced Channel Management and Accuracy

The system includes an inlet line selector (multiplex) with miniature solenoid valves, allowing flexible channel switching between multiple bioreactors. After each switch, gases pass through PTFE filters that prevent particle and liquid contamination. Moreover, integrated microflow regulators maintain constant flow through the transducers, ensuring high measurement accuracy. In addition, temperature compensation and probe calibration features provide reliable results across microbial and cell culture workflows.

High-Performance Components and Automation

Metis leverages minimal-volume transducers and high-precision moving parts to enhance gas interchange and reliability. Additionally, a PLC board manages all integrated components, while real-time data acquisition converts sensor signals into meaningful process values. Consequently, users can adjust channel configurations, analyze multiple gas sources, and export graphs with dynamic zoom and scale adjustments.

Software Integration and Workflow Efficiency

The included software supports integration of 1–8 gas sources for analysis, providing parallel monitoring of multiple bioreactors. As a result, researchers can control data acquisition, configure measurement channels, and perform real-time calculations for improved reproducibility. Finally, the system’s intuitive HMI allows seamless management of all parameters, facilitating efficient workflows for laboratory professionals.

Explore Apex Scientific’s Insights page to learn more about implementing gas analyzers for bioreactors in South African laboratories. Contact us today to discuss your laboratory equipment requirements.