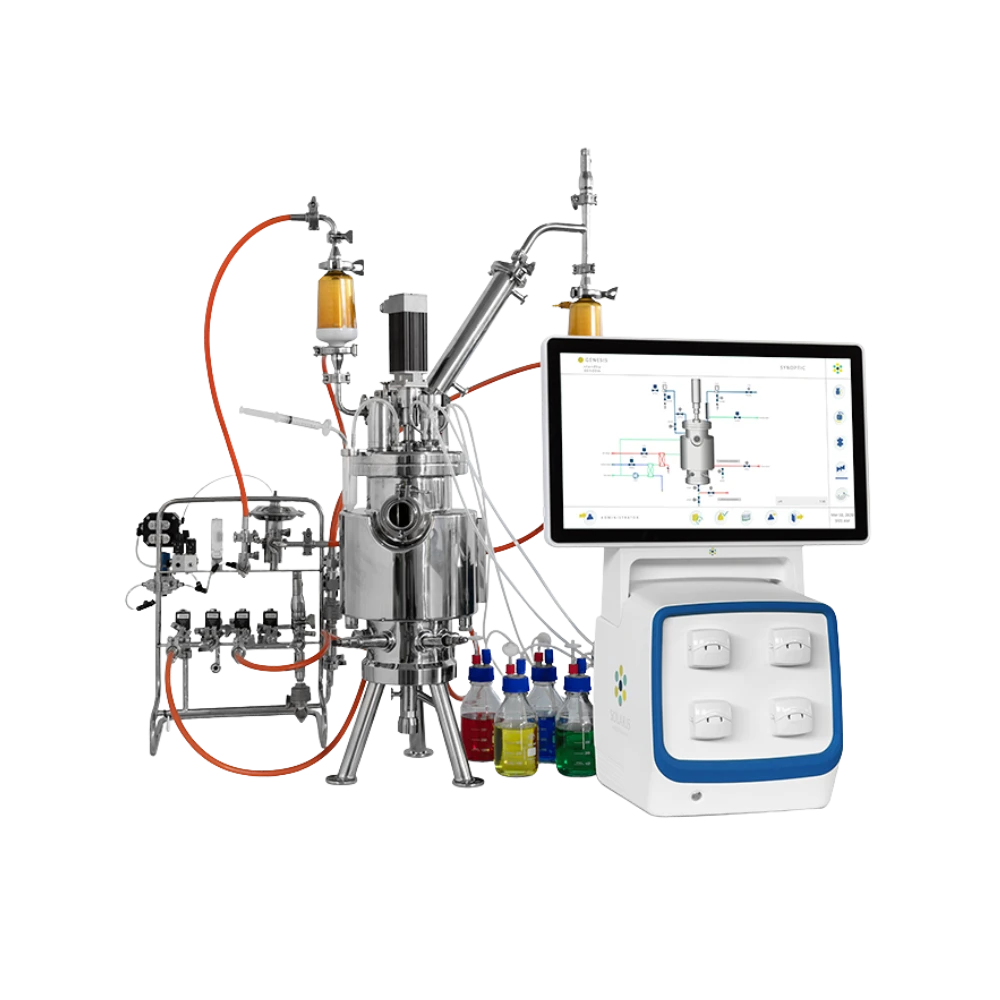

The large laboratory bioreactor or fermenter systems from Solaris Biotech provide versatile, high-performance solutions for laboratory fermentation. Designed for both single and parallel operations, these stirred, autoclavable bioreactors include in-situ sterilization (SIP). This feature allows reliable sterilization of harvest and sample lines throughout the fermentation process. Available in 7.5, 10, 15, and 20 L capacities, the GENESIS bioreactor supports aerobic and anaerobic fermentations. It ensures closed aseptic operation, making it ideal for research laboratories in South Africa seeking precise, reproducible results.

Efficient Sterilization and Temperature Control

The GENESIS system uses steam, electrical heaters, or a hybrid steam/electrical method for sterilization. Additionally, jacketed designs on the side and bottom enhance heat transfer and maintain optimal temperature control. The AISI 316L stainless steel vessel supports microbial and cell culture configurations, including Toro spargers, Rushton impellers, Marine impellers, and baffles. These options increase flexibility for various fermentation applications.

Advanced Monitoring and Automation

Digital Modbus sensors minimize background noise and provide rapid response times. Moreover, comprehensive measurement and control options accommodate batch, fed-batch, and continuous processes. Gas mixing strategies support up to five TMFC, and brushless motors ensure precise stirring. Optional analog I/O connections and a wheeled skid improve workflow and system flexibility.

Integrated Software for Parallel Management

Solaris Biotech’ Leonardo SCADA software allows up to 24 bioreactors to run in parallel from a single HMI. Users can access real-time 3D views, manage profiles, assign peristaltic pump functions, and export data in .csv format. Furthermore, remote monitoring is possible via PC, tablet, or smartphone, improving workflow efficiency.

Explore Apex Scientific’s Insights page to learn more about large laboratory bioreactors and fermenters. Contact us today to discuss your laboratory equipment requirements.