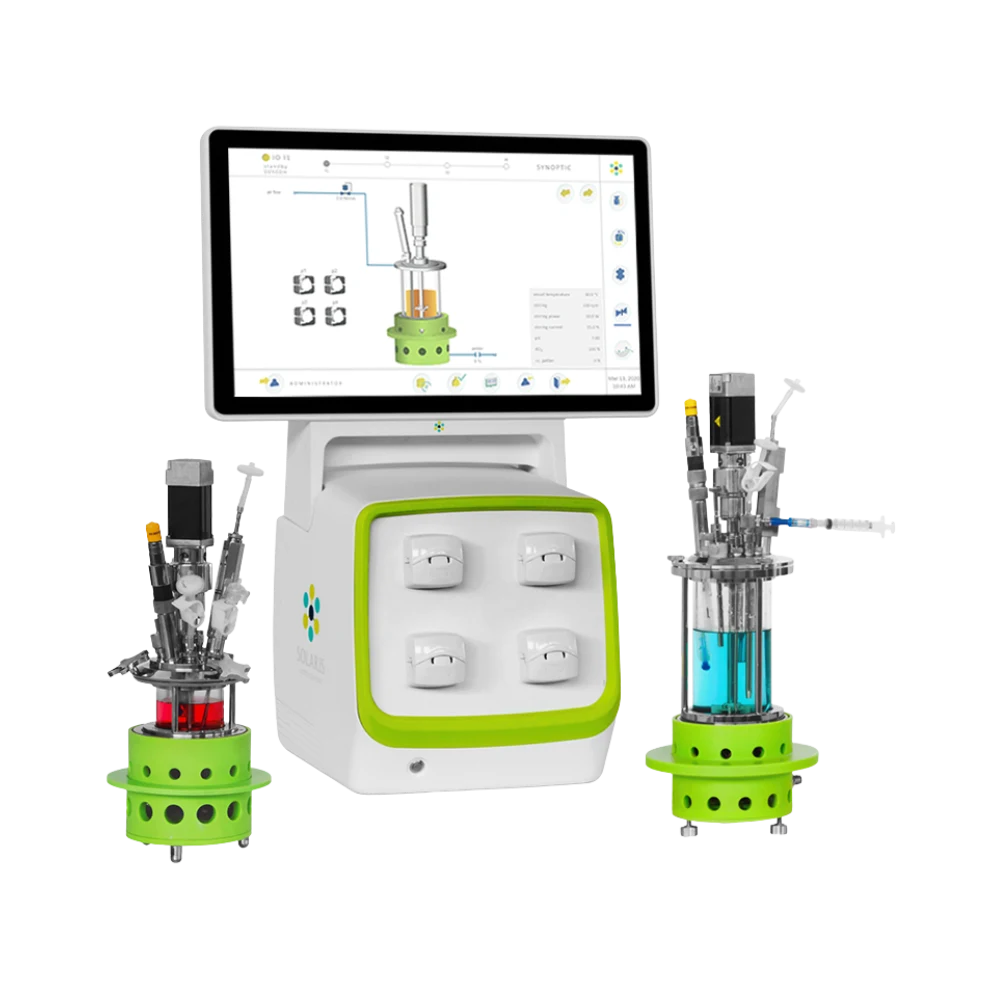

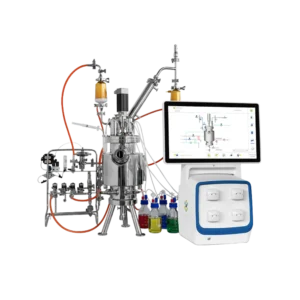

The mini benchtop bioreactor or fermenter from Solaris Biotech offers a flexible, precision-controlled platform for advanced laboratory research and process development. Designed for single or parallel experiments, this compact, mini system is fully autoclavable and features a highly efficient stirred configuration. It ensures reliable fermentation workflows for scientists across South Africa. Supported locally by Apex Scientific, it delivers the performance and adaptability required for academic and industrial bioprocessing.

Innovative Design

The Solaris IO uses a single-wall borosilicate glass vessel with Peltier-based thermoregulation, so no external chiller or water circulation is needed. Working volumes of 200 ml or 1000 ml allow smooth scale-up or scale-down. Configurations support microbial (aerobic or anaerobic) and cell culture applications. In addition, users can select Rushton, Marine, or Pitched-Blade impellers and optional fluted or L-shaped spargers to match experimental goals.

LEONARDO 3.0: Advanced SCADA Control

The innovative SCADA software LEONARDO 3.0 is a smart, user-friendly controller that provides advanced automated management of fermentation and cultivation processes. Supplied in its full version with the equipment, it can manage up to 24 units in parallel through a single 24-inch HMI. Users can extract data in .csv format and enjoy convenient remote access via PC, tablet, or smartphone using QR code scanning or a dedicated portal, while remote control capabilities also enable efficient after-sales assistance.

Advanced Measurement and Control

Comprehensive monitoring covers temperature, pH, dissolved oxygen (dO₂), dissolved carbon dioxide (dCO₂), redox potential, antifoam, level, conductivity, weight, and cell density. Moreover, Modbus digital sensors reduce background noise and provide rapid response times. A powerful 1 RPM brushless motor drives precise agitation. The LEM01 PLC-based control system also integrates four fixed or variable-speed peristaltic pumps for accurate fluid management.

Sterile sampling system

Leda is an innovative sterile sampling system for Solaris autoclavable fermenters and bioreactors, enabling up to 180 sterile samplings per batch. Featuring a needle-free connector and a sterile syringe–non-return valve combination, it minimizes contamination risk and maintains sterility between uses. The entire system is autoclavable at 121–133 °C for up to 30 minutes.

Flexible Operation

The mini benchtop bioreactor supports batch, fed-batch, and continuous processes. Furthermore, it offers gas mixing strategies with up to five thermal mass flow controllers or solenoid valves. An optional gas-out condenser with a Peltier cell further stabilizes operations. Despite these features, the footprint remains extremely compact, saving valuable bench space in any laboratory.

Applications

This mini fermenter and bioreactor excels in basic research, education, process development, media optimization, and small-scale production. Consequently, researchers gain dependable performance and easy scalability for pilot or production environments.

Learn more about Apex Scientific’s full range of Solaris Biotech equipment and access detailed technical guidance by visiting the Apex Scientific Insights page.