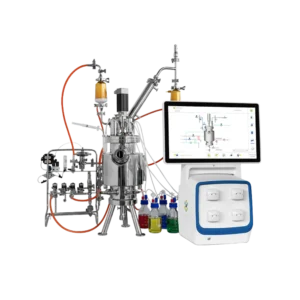

Introducing Solaris Benchtop Bioreactors + METIS Gas Analyzer

In the world of biotech, pharmaceutical development, synthetic biology, and cell therapy, moving from concept to scalable process is a key hurdle. Consequently, the benchtop scale remains the critical zone where hypothesis meets reality, where process design, optimization, and scale-down/scale-up strategies are fine-tuned. That’s why we are excited to expand our product portfolio with Solaris Biotech’s benchtop bioreactors and the METIS gas analyzer—a suite engineered to bring flexibility, precision, and robustness to upstream workflows.

Why Solaris Benchtop Matters

Solaris is known for offering bioreactor systems across scales, from lab to industrial. Moreover, their benchtop portfolio delivers several advantages for R&D, process development, and scale-down studies:

- Compact, modular, user-friendly design—ideal for lab benches or parallel arrays while still offering full control capabilities.

- Parallel control and software integration—operate up to 24 units in parallel under one control framework (Leonardo software), therefore enabling combinatorial experiments or screening workflows.

- Open communication protocols & digital sensors (Modbus, etc.)—supports data traceability, reduces noise, and ensures robust signal handling.

- Flexible vessel types & sterilization modes—choose autoclavable, SIP, or single-use designs suitable for microbial as well as cell-culture workflows.

- Scalable architecture—configurations align with pilot and production units, thereby easing scale-up challenges.

In short, Solaris benchtop systems are engineered not just for small-scale convenience but for serious process development.

Solaris Benchtop Portfolio: Choosing the Right Platform

Because each project is unique, Solaris offers several platforms to match different needs:

| Platform | Working Scale / Typical Volume | Key Features & Target Uses |

|---|---|---|

| IO | 200 mL & 1 L | Electric, mini stirred bioreactor with rapid, accurate thermoregulation (no water recirculation). Ideal for media screening, strain optimization, and early process development. |

| Jupiter | 2 L to 10 L | Autoclavable or jacketed stirred variants; optional pressure control (up to ~1.6 bar). Supports batch, fed-batch, and continuous modes—therefore highly configurable for scale-down or scale-up studies. |

| ONE | 2 L | Integrated Wi-Fi, fully automated control, and precise stirring, temperature, pH, and DO regulation. As a result, it combines ease-of-use with robust performance. |

| Genesis | 7.5 L to 20 L | Sterilizable-in-place (SIP) reactor with automated steam or electric sterilization. Perfect for bridging lab to pilot scale and demanding fermentations. |

| METIS (Gas Analyzer) | N/A | Off-gas analyzer for O₂/CO₂ monitoring. Computes OUR, CER, and RQ in real time, thus providing metabolic insight. |

For example, IO is best for early screening, whereas Genesis supports pilot-scale bridging.

Unleashing Insights with METIS Gas Analytics

One of the most powerful levers in fermentation or cell-culture design is metabolic insight. Therefore, knowing how the culture consumes oxygen, produces CO₂, and shifts its respiratory quotient is essential.

The METIS gas analyzer excels here:

- Real-time O₂ and CO₂ off-gas monitoring provides continuous metabolic data instead of mere endpoint measurements.

- Calculation of OUR, CER, and RQ enables rapid adjustments to aeration and feeding strategies.

- Seamless integration with SCADA or Galileo software allows data visualization, export, and merging with other process streams.

- Built-in calibration and temperature-compensation features further ensure accuracy.

Because of these capabilities, coupling METIS with any Solaris bioreactor delivers deeper real-time insight and faster process optimization.

Where Solaris Benchtop Systems Fit in Modern Pipelines

These systems shine in several scenarios:

- High-throughput strain/media screening: Multiple IO units can run in parallel under unified software control. Consequently, researchers can quickly compare induction conditions or media recipes.

- Process development & scale-down studies: Jupiter or ONE offer advanced gas cascades and pressure control while maintaining a benchtop footprint.

- Pilot bridging and scale-up prototyping: Genesis provides SIP functionality and larger volumes, therefore transferring data directly to pilot-scale operations.

- Metabolics-informed control: METIS enables feeding or aeration strategies based on metabolic rates, thus detecting culture stress earlier than biomass or DO sensors.

- Parallel optimization & data-driven iteration: Up to 24 units can run under one HMI, so Design-of-Experiments (DoE) can be executed in real time.

Best Practices for Adoption

To maximize performance, keep these points in mind:

- Sensor calibration & validation: Even digital sensors require periodic checks. Therefore, consistent calibration ensures trustworthy data.

- Mixing and oxygen-transfer scaling: Use small-scale kLa and mixing data so that scale-up design is accurate.

- Sterilization and cleaning validation: For Genesis, validate steam or electrical sterilization cycles and map potential dead zones.

- Data integration: Leverage open protocols for LIMS or SCADA connectivity, thereby simplifying trend monitoring and alarms.

- Parallel experiment planning: Careful DoE layout furthermore helps fully utilize parallel capacity.

Conclusion: A New Chapter in Lab-Scale Bioprocessing

By adding Solaris Bioreactors (IO, Jupiter, ONE, Genesis) and the METIS analyzer to our portfolio, we open a powerful new channel for researchers, bioprocess engineers, and innovators across biotech, pharma, food, and beyond.

Ultimately, these instruments are not merely smaller versions of production gear; they are process-enabling tools that deliver control, insight, scalability, and flexibility at the bench. Whether you are optimizing a microbial pathway, working on mammalian cell culture, or designing new biomanufacturing routes, this suite empowers your exploration.