Freeze Dryers

What is Freeze Drying?

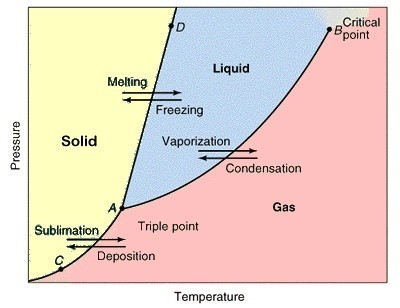

Freeze Drying is a process in which a completely frozen sample is placed under a vacuum in order to remove water or other solvents from the sample, allowing the ice to change directly from a solid to a vapor without passing through a liquid phase. This process, called sublimation. Along with the minimal heat input that is required, this method is ideal for long-term preservation. The integrity of the sample’s biological and chemical structure remains intact due to the minimal heat input.

Applications

- Food Industry – Food freeze dried so that it can be preserved for long periods. Important for astronauts, hikers, military. Food dehydrated to prolong shelf life and freshness eg noodles, soup and instant coffee

- Dairy Industry – Dairy products that usually required refrigeration can be preserved for long periods by freeze-drying. This is advantages because it does not require additional chemical additives and volume of product is reduced enabling easier transportation.

- Nutraceuticals – Nutraceuticals are products derived from food that can be used to promote well-being Eg Aloe Vera, Tea, Sea-weed. Freeze drying promote stabilization and shelf-life

- Starters and Cultures – Eg, Probiotics, Buttermilk. Regular drying will decrease efficiency and may cause adverse changes to starters and cultures. Freeze drying enables the culture to be more effective.

- Pharmaceuticals – Increase shelf life of drugs and vaccines. A liquid drug can be converted to a powder form and stored in a vial. It can be reconstituted when ready to use. Pharmaceuticals that are freeze dried include proteins, antibiotics, hormones, vaccines, plasma etc.

- Research – Botanical samples are preserved by freeze drying for research purposes. Laboratory samples that can be preserved by freeze drying include active pharmaceuticals, pathological samples, microbial cultures, viruses, bacteria, antibodies etc

- Document Recovery – Freeze drying can be used for recovery and saving documentation damaged by water, fire etc.

- Floral – The moisture content in flowers can be eliminated by freeze drying while still preserving is shape, structure and quality.

- Taxidermy – Freeze drying can be used to aid taxidermy

- Pet Food – Removal of moisture is important for long term preservation of petfood. Regular drying can affect quality and impact nutrition. Freeze drying can be used to preserve pet food without adversely affecting the quality if the pet food.

Other Names:

Lyophilization, Cryodesiccation.

Working Principal

Freeze drying occurs in three phases:

- Freezing

- Primary Drying (Sublimation)

- Secondary Drying (Adsorption)

Freezing Phase: The sample is frozen, which means the water in the product is converted to ice, thereby the phase has changed from liquid to solid. Slow pre-freezing will produce larger ice crystals, which are easier to freeze dry, whilst fast pre-freezing results in smaller crystals.

Primary Drying (Sublimation) Phase: In the second stage the sublimation process starts. The ice formed in the pre-freeze step is removed from the sample by the direct transition of the “solid” ice to a vapour without passing through a liquid phase. The resultant vapour is collected in the condenser, which has a lower temperature and pressure than the product. The vapour is thus converted back to ice on the condenser surface. The “energy” required for this process to occur is provided by a gentle heating of the sample, which will start the sublimation process and eventually the sample will dry. If too much energy (heat) is applied to the sample during this stage the condenser may not be able to condense the volume of vapours fast enough, the ice condenser temperature will subsequently rise along with its vapor pressure, thus increasing the risk of the sample melting.

Secondary Drying (Adsorption) Phase: Finally, any residual water present, which is strongly bound to the molecules of the sample, is converted to vapour and removed from the sample. This water has invariably a vapour pressure lower than that of water in its “free” form. Removal of the water in this final stage will be performed at higher product temperatures, consequently, any biological activity of the sample will not be impaired or affected. This usually involves increasing the temperature and lowering the pressure to provide enough energy to break down the molecular bonding. A process called desorption.

Operating Procedure

- Position equipment in a suitable well ventilated dry location, where it will not be moved or knocked during operation. Ensure the equipment is at least 30cm away from surfaces or other equipment, and not operating near heat generating equipment, ambient temperature must be in the range +10℃ to +25℃. Ensure good airflow around unit vents.

- The ice condenser chamber must be clean and dry before commencing. Ensure the drain valve is CLOSED. Ensure the ice condenser chamber is clean and dry – water residues from the preceding drying run must be removed with a clean dry cloth.

- Check the level of vacuum pump oil is within the range of minimum and maximum on the glass window at the rear of the pump before starting. Check the liquid level in the collecting vessel of the filter. Pump oil level and condition of the oil should be checked at regular intervals, and topped up as necessary with supplied oil. Discharged Oil mist is captured in the oil mist separator to prevent discharge into the room. Condensed oil mist must be periodically removed.

- Plug power cord in, ensuring the power cord is not exposed to damage from heat or other damage.

- Product that is to be dried must be prefrozen – either directly in the freeze dryer or in a separate deep freeze.

- Layer thickness of 1-2 cm should not be exceeded. Liquids should be no more than 1cm, unless a spin freezing device is used to create a thin drying layer.

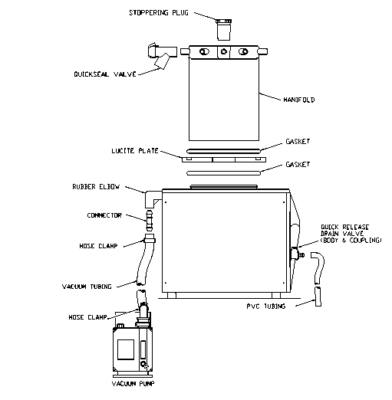

- Place the manifold on the top of the condenser. If needed a very thin layer of vacuum grease may be applied to seals to ensure a good seal under vacuum.

- Ensure valves of all accessories are closed

- Turn on the mains switch on the unit

- Turn on the condenser – Condenser will reach lowest temperature (depending on model)

- Switch on the vacuum pump

- Once the pump reached 100mTorr you can start adding samples. If using a manifold – attach flasks individually to begin the freeze drying process. Do not add additional flasks until the vacuum has recovered to at least 200 millitorr.

- Monitor Process – Insure that system parameters (refrigeration and vacuum) stay within normal ranges. Check condenser ice build-up periodically. Observe the product to determine if drying is complete. For Manifold Drying, the process is complete when the outside of the flask loses condensation and the product appears dry.

- Remove Product – For Manifold Drying, close Quickseal Valves and remove flasks.

- Shutdown Unit – Release vacuum from the system by inserting the drain line or opening a Quickseal Valve.

- Switch off vacuum

- Switch off refrigeration

- At the end of drying switch the vacuum pump off and aerate the drying chamber via the media drain valve or rubber valve. Remove the Drum Manifold, remove samples. Place the unit in standby mode.

- Defrost condenser either manually for via hot gas purge (see manual)

- SWITCHING OFF Freeze dryer must be in stand-by mode. Switch off the mains switch.

Different types of Freeze Dryers

Freeze dryers can be informally classified by the type of product chamber:

- Manifold dryers where the product is typically pre-frozen & in flasks

- Shelf dryers where the product is placed in a tray or directly on a shelf

- Combination units with both drying options.

Freeze-dryers can also be grouped by size & use:

- Laboratory bench-top units for R&D

- Pilot units for process development and scale-up

- Production-sized units. It should be noted that in addition to process scale-up work, pilot-sized freeze dryers are often used for product R&D as well as small volume production applications.

Choosing a freeze dryer depends on the product characteristics as well as many other application-based variables including the container that the product will be dried in, the shelf area or number of ports required to accommodate the quantity to be dried in each batch, the total volume of ice to be condensed and whether there are any organic solvents. The type and shape of product being dried and its end-use also need to be considered.

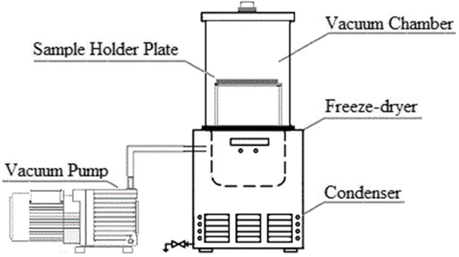

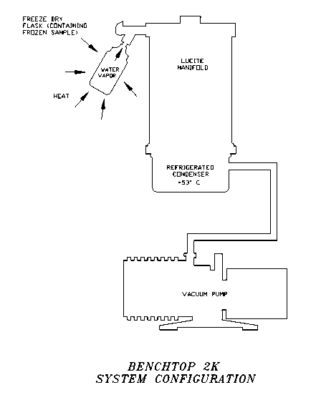

Basic Layout

Benchtop / Manifold Freeze Dryer

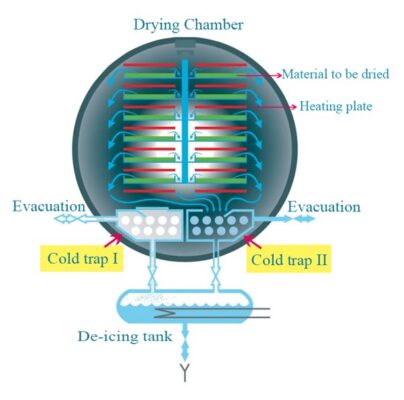

Shelf Freeze Dryer (Internal Condenser)

Shelf Freeze Dryer (External Condenser)

Important Accessories

- Vacuum Pump

- Oil mist filter / Odour Filter

- Vacuum Grease

- Manifold

- Gaskets

- Vacuum Clamps

- Shelf

- Stoppering Shelves

- Freeze Drying Flasks and assembly

- Roundbottom flasks

- Trays

- Vacuum Baffle Plate

Maintenance

Vacuum Pump: Clean oil is necessary for the best vacuum and efficiency of the complete system. Checking and changing the oil on a consistent basis will greatly extend the life of the vacuum pump. Vacuum Pump Oil should be changed on an “as-needed” basis by checking the oil after each freeze drying run. The following is a basic guideline to visually checking the oil. Drain a small amount (approximately 100 mL) of oil from the pump drain line. Use a clear container to capture the sample.

- Pale yellow or clear vacuum pump oil – indicates good condition

- Dark vacuum pump oil – indicates acid contamination

- Cloudy grey vacuum pump oil – indicates water contamination

Gas ballast Valve on the Vacuum Pump: The gas ballast valve removes moisture (water, alcohol etc…) from the pump oil. During freeze drying or cold trap use, vapors could bypass the condenser and end up in the vacuum pump. If this happens the vapors will degrade the oil causing excessive wear as well as higher vacuum pressure.

When the ballast is open, it allows a controlled amount of air into the second stage pump cylinder. This reduces the partial pressure and increases the pump’s operating temperature in order to release vapors.

Gas Ballast Procedure:

- Wait for the vacuum pump to reach normal operating temperature (70-80 degrees C)

- Open the Gas Ballast while the pump is operating.

- Leave the Gas Ballast open for 45-60 minutes while the pump is operating. This is usually sufficient to remove all of the condensables from the oil.

- Remember to close the gas ballast valve when finished. Operating the pump with the gas ballast valve open causes slightly higher ultimate pressure, increased oil consumption and an oil mist exhaust.

Oil Mist Filter – Check if oil has collected. Drain the Oil

Condenser: The condenser is fabricated from stainless steel and under normal use can be rinsed and kept clean with a mild detergent. If corrosive materials are being freeze dried, then thoroughly clean and rinse all parts of the freeze dryer that come in contact with product moisture. This prevents residual build-up of corrosive and contaminating materials on interior surfaces, protecting the freeze dryer and the next product to be processed. Add baking soda or any mild buffering agent to the rinse water to help neutralize acidic residue. Note: A siphon type squeeze bottle can be used to direct the rinse spray into difficult to reach areas. Failure to properly neutralize corrosive materials will damage your freeze dryer and void the warranty. Never allow the condenser to fill to more than half full of liquid to avoid causing liquid back flow into the vacuum pump.

Acrylic Cover: Clean acrylic cover with a mild detergent. Do not use organic solvents or abrasive cleaners.

Vacuum Tubing and Gaskets: Inspect tubing and gaskets periodically for signs of age such as cracking or a dried appearance. Check gaskets by removing and inspecting interior surfaces for potential problems. A light coating of Vacuum Grease on the exterior surfaces will protect gaskets and tubing. Replace as needed.

Refrigeration: Check and periodically clean grill when unit is shutdown. Efficiency of the refrigeration unit is greatly affected by the condition of the grill under the benchtop. If the grill becomes clogged with dirt and dust, the fan cannot pull air through it. Without this airflow, the condenser will not properly cool the refrigerant or cool the compressor motor. A soft brush or vacuum cleaner can be used to remove dirt and dust.

Important Terms

Condenser: In terms of the lyophilization process, this is the vessel that collects the moisture on plates and holds it in the frozen state. Protects the vacuum pump from water vapor contaminating the vacuum pump oil.

Contamination: ln the vacuum system, the introduction of water vapor into the oil in the vacuum pump, which then causes the pump to lose its ability to attain its ultimate pressure.

Defrosting: The removal of ice from a condenser by melting or mechanical means.

Hot Gas Defrost: Uses refrigerant vapor from the compressor discharge as a heat source to melt the ice in the condenser.

Oil Mist Filter: A filter attached to the discharge (exhaust) of an oil-sealed rotary pump to eliminate most of the “smoke” of suspended fine droplets of oil which would be discharged into the environment.

Prefreezing: The process of cooling a product to below its eutectic temperature prior to freeze drying.

Secondary Drying: The process of reducing the amount of bound water in a freeze dried product after primary drying is complete. During secondary drying, heat is applied to the product under very low pressures.

Shell Freezing: Freezing a product in a thin layer that coats the inside of the product container. Shell freezing is accomplished by swirling or rotating the product container in a low temperature bath

Bound water: Water strongly bounded to the product with a relatively high bounding energy and whose presence in the product is necessary for the stability of the material. This does not take part in the freezing process.

Cake: The porous and spongy structure-like material resulting from the lyophilization process; or the solid content remaining after the freeze drying process.

Collapse: The point at which the product softens to the extent that it can no longer support its own structure.

Condenser: The component of a vacuum freeze dryer that is designed to remove solvent vapor (mainly water vapor) from the gases in the chamber to prevent them from reaching the vacuum pumping system.

Critical Temperature: During freeze drying, the maximum temperature of the product before its quality degrades by melt-back or collapse.

Desorption: Also known as secondary drying; this process involves the removal of excess moisture (bound water) by increasing the temperature of the product and reducing the partial pressure of water vapor in the container.

Eutectic Point or Eutectic Temperature: The point at which the product only exists in the solid phase, representing the minimum melting temperature. Not all products have a eutectic point, or there may be multiple eutectic points.

Leak Rate: Unit of measurement in which the medium being measured (contained system) has a defined decay over a unit of time. Typical usage would include a loss of vacuum pressure over a time interval.

Melt-back: The total collapse of a given formulation resulting from the presence of a liquid during the primary drying phase.

Sublimation: Also known as primary drying; after the material is completely frozen, the pressure in the freeze dryer is reduced, and heat is applied to initiate the sublimation of the ice crystals, which removes the unbound moisture from the product. Less specifically, sublimation is the transition from a solid to a gas phase with no intermediate liquid stage.

Who can we sell to?

- Universities: Microbiology, Biochemistry, Botany, Civil Eng, Chemistry.

- Pharmaceutical Companies

- Food Manufacturing Companies

Questions to ask customers

- Does your sample contain any organic solvents or is it aqueous?

- Describe what type of samples you will use

- What is the Freezing point of your sample?

- Do you have a suitable freezer for pre-freezing?

- In what container you like to freeze dry your samples?

- Flasks, tubes, vials, or trays? Please elaborate size and of container and size of individual samples

- What is your total sample volume per run (in litres)?

Further Reading

https://www.spscientific.com/LearningCenter/

https://www.labconco.com/articles/5-questions-to-ask-before-buying-a-freeze-dryer

https://www.sciquip.co.uk/faq-freeze-dryers