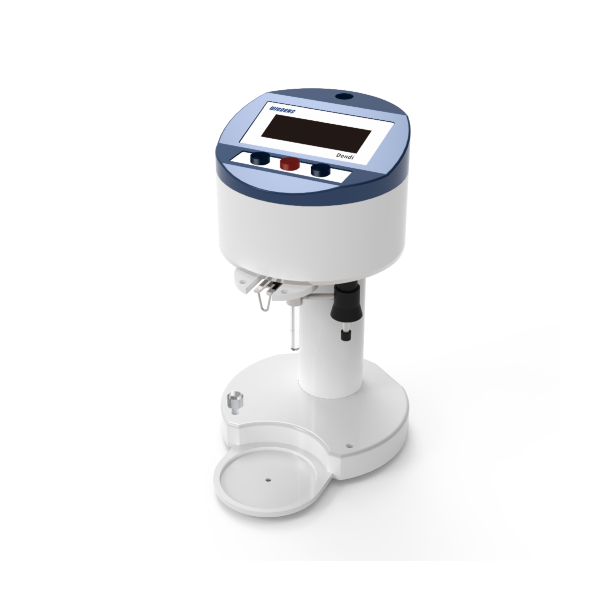

Principle of operation

The operating principle of the device is – weighting of the glass float with filler fully immersed in liquid. It allows measuring observed density and temperature of wide range of opaque and transparent liquids. The buoyancy force of liquid acts on the float, which has precise weight and volume; the float’s movement is transmitted to the beam with balance. The electronics employ sophisticated signal processing and computational algorithms to deliver high accuracy measurements. The device has a rugged design with little need for service and easy cleaning. The calibration requires only distilled water. Built-in tables of water densities at testing temperatures and air density (average value for standard european conditions) allows to determine linear dependence of density and weight (see graph on top). Taken together these features result in a device with a long service life and very low cost of ownership.

- Wide range of supported measuring units

- Covered Density range: 500…2 000 kg/m³

- Automatic measurements

- Simple in operation, safe

- Density/Concentration and Temperature measurements in one instrument

- Unit conversion

- Automatic temperature compensation

- No experienced personnel required

Preparation of the Samples

- Liquids for measurements must be gas-free and their temperature must be equal to the ambient temperature ±5℃ .

- If the same beaker is used for various liquids clean it thoroughly and dry before filling with new sample!

- For accurate sample preparation place the float into the beaker and fill it with measured liquid up to the top.

- Place the beaker to the special tray on the base of the device and set the float on the measuring arm – to ensure that the level sample is 2-4 mm above the float.

- Then you may take the float off the beaker and make a mark on the beaker with the help of marker for glass.

Preparation of the Device

- Make an external survey of the float and other submersible parts. They must be clean and dry, without mechanical injuries. Any dents or impurity adhered on the float will influence the accuracy of the density measurements!

- In case of impurity – wash the float in appropriate solvent and dry it with some non-fluffy material (paper towel, rags, etc.).

- Set and remove the float on the measuring arm – to check its free running. All the time take care of cleanness in the inlet of the measuring arm!

- Set the device on the workplace and adjust its horizontal position (in accordance with level vial) with the help of adjusting screws.

- Switch ON the device and warm it up for 10 minutes.

Specifications

| Model | DenDi-1 |

| Measuring range | |

| Density | 0… 3 g/cm³ (0… 3000 kg/m³) |

| Density Standard | 0.6… 1.2 g/cm³ (600… 1200 kg/m³) |

| Temperature | +15… +30℃ (+59… +86° F) |

| Accuracy | |

| Density | ±0.0005 or ±0.001 g/cm³ (±0.5 or ±1.0 kg/m³) |

| Density Standard | ±0.2℃ (±0.4° F) |

| Repeatability | |

| Density | ±0.00025 or ±0.00050 g/cm³ (±0.25 or ±0.50 kg/m³) |

| Temperature | ±0.1℃ (±0.2° F) |

| Supported Measuring Units | |

| Observed/Relative Density | g/cm³, kg/m³, lb/gal, lb/ft³; API; SG |

| Base Density | at 15℃ , 20℃ , 60° F; API60; SG60 |

| Tables | ASTM D1250 |

| Alcohol Tables (volume%) | ºBx, ºP |

| Temperature | ℃ or ° F |

| Ambient Temperature | +15… +30℃ (+59… +86° F) |

| Sample Volume | 100 ml (26.4·10 gal) |

| Power Supply | NiMH 9V-150 mAh |

| Operating Time without Charging | Appr. 12 hours |

| Dimensions (H x L x W), Weight | 135 x 100 x 190mm, 1.3 kg |

| 135 x 100 x 190mm, 1.3 kg | Automatic |

| Delivery | Delivered in compact carrying case |