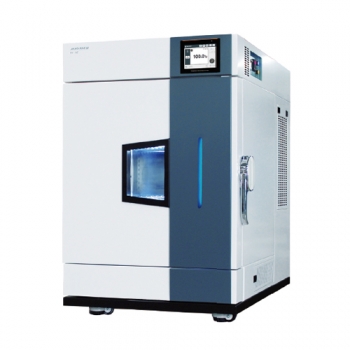

Optimized Model Configuration

- 2 series (KE, ME) according to temperature control range.

TC3-KE ; -35 ~ 150℃

TC3-ME ; -20 ~ 150℃ - Standard type Temp. & Humid chamber for selecting the optimized model according to test conditions.

- Dedicated stand for convenient use and moving.(option)

- Recorder for maintaining test records. (option)

Structural functional features

- Proven reproducibility and reliability with structural design optimized for miniaturization.

- Compact design for excellent space saving.

- Excellent thermal insulation and sealing to ensure stable temperature and humidity reproducibility even for repeated test use.

- The door part has a double sealing structure and excellent air tightness.

Use Convenience Features

- Convenient operation with 5.6 inch color touch display controller.

- Easy observation of samples with tempered glass door with built in heating wire and LED lamp.

- By displaying the operation status of the device with LED colors, convenient to identify chambers status from a far.

- The cable port(ø 50 mm) included as standard make it convenient to connect external equipment.

- The door structure can be easily opened or closed.

- Door handle with built-in key lock.

- Identification of the control and operating conditions at the front of the product.

- Design by stainless steel internal chamber made of stainless steel provide clean maintenance and excellent corrosion resistance.

- Easy to clean as it is easy to remove refrigerator condenser grill, making it convenient to maintain efficiency of refrigeration.

- Equipped with easy-to-move/install caster.

Multi-function Control System

- Highly-reliable control through calibration.

- Auto-tuning by subdivided PID zone for more precise control stability.

- RS-232 port (default) and RS-485 port (option) supported.

- Control and data v processing by connecting up to 32 devices to PC at same time via RS-485 port.

- Convenient checking with useful graph display.

| Description | No. |

|---|---|

| Pattern | 100 |

| Repeat time | 999 |

| Part repeat time 255 |

255 |

| Max. segments / pattern | 100 |

| Available max. segments | 2000 |

| Programmable process time / segment | 99 hour 59 min. |

* It is possible to set 100 segments per pattern, but the maximum number of segments is not 10,000 (100 pattern x 100 segment) but 2,000.

Outstanding Safety

- Electronic over temperature protection system.(A-OT, advanced over temperature limiter)

Independent precision temperature sensor and controller for safer and more accurate over temperature shutdown. - Conventional over-temperature protection.(B-OT, backup over temperature limiter)

A backup device for electronic system failure, mechanically preventing over temperature even when it occurs electronic errors. - Door open warning and automatic shut off.

- Over-current and short circuit protection of device.

- Each heater has fuse for more being safe use.

- Automatic stop when operating current of refrigerator is overloaded.

- Automatic stop in case of over temperature of the compressor.

- Auto shut off in case refrigerant pressure (high/low pressure) is abnormal.

|

|

|

|

| Viewing window | Indicator LED of product condition | Cable port | Door handles & Locking device |

Technical Specifications

| Model | TC3-KE-025 | TC3-KE-065 | TC3-KE-100 | |

|---|---|---|---|---|

| Temperature data | ||||

| Range (℃ / ℉) | -35 to 150 / -31 to 302 |

-35 to 150 / -31 to 302 |

-35 to 150 / -31 to 302 |

|

| Fluctuation (±℃ / ℉) 1) | 0.3 / 0.54 | 0.3 / 0.54 | 0.3 / 0.54 | |

| Variation (±℃ / ℉) 2) | 0.5 / 0.9 | 0.5 / 0.9 | 0.5 / 0.9 | |

| Heating time 3) | 60 | 60 | 60 | |

| Cooling time 4) | 70 | 70 | 70 | |

| Interior dimensions | ||||

| Chamber volume (L / cu ft) | 25 / 0.88 | 65 / 2.3 | 100 / 3.53 | |

| Width (mm / inch) | 350 / 13.8 | 400 / 15.7 | 500 / 19.7 | |

| Depth (mm / inch) | 220 / 8.7 | 330 / 13 | 380 / 15 | |

| Height (mm / inch) | 350 / 13.8 | 495 / 19.5 | 530 / 20.9 | |

| Quantity of shelves (standard/max.) | 2/7 | 2/10 | 2/10 | |

| Distance of between shelves (mm / inch) | 20 / 0.8 | 20 / 0.8 | 20 / 0.8 | |

| Max. load per shelf (kg /lbs) | 25 / 55.1 | 25 / 55.1 | 25 / 55.1 | |

| Permitted total load (kg / lbs) | 65 / 143.3 | 65 / 143.3 | 65 / 143.3 | |

| Cable port (Ø, mm / inch) | 50 / 2 | 50 / 2 | 50 / 2 | |

| Weight (kg / lbs) | 110 / 242.5 | 140 / 308.6 | 150 / 330.7 | |

| Electrical requirements |

AC230V, 1ph, 60Hz | 7.4A | 8.8A | 10.8A |

| Cat. No. | AAH861131K | AAH861231K | AAH861331K | |

| AC230V, 1ph, 50Hz | 7.4A | 8.8A | 10.8A | |

| Cat. No. | AAH861132K | AAH861232K | AAH861332K | |

※ The above specifications are tested according to DIN 12880 and IEC 60068 standards.

※ Permissible environmental conditions are 18 – 30°C (recommended 20°C), 85% RH or less, under 2000m above sea level.

- The set value is set under the conditions of 100°C.

- The set value is set under the conditions of 25°C.

- TC3-KE : -40℃ to 100℃(-40℉ to 212℉), TC3-ME : -20℃ to 100℃(-4℉ to 212℉)

- TC3-KE : 20℃ to -40℃(68℉ to -40℉), TC3-ME : 20℃ to -20℃(68℉ to -4℉)

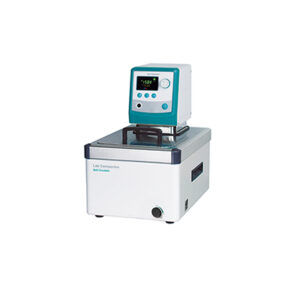

Accessories & Options:

- Cable Port: Both cap and silicone plug are included as standard in Ø50 mm cable port. It is available to add Ø50 mm, Ø80 mm.

- Wire Shelf: Excellent ventilation structure. Stainless steel. Includes 2ea as standard.

- Perforated Shelf: Suitable for high-load samples. Excellent maintenance as made of stainless steel.

- Viewing Window: Constantly observing the samples under test in anytime. Tempered glass window with wire heater and LED lamp.

- Signal Lamp: Figuring out equipment status remotely. Run/Stand-by/Error displayed by color.

- Recorder (Paper): Up to 6 channels supported. Set recording range and speed. Paper width: 100mm.

- Recorder (Digital): Paperless. (5.7″ LCD Display) Up to 6 channels supported. Data stored in internal/external memory.

- Gas Purge System: Gas system that can replace and purge the inside of chamber with nitrogen and CO2 gas.

- Hour Meter: Cumulative usage time management. (No reset function) Minimum units of measurement: 0.1 hours. (6 minutes) Maximum display 99999.9 hours.

- Stand (1 Stage): Dedicated stand for small appliances. Provides Lower drawer and loading space. Casters provided as standard for moving/fixing.

- Stand (2 Stage): Placing of two compact devices vertically. Minimized installation space for different temperature and tests.