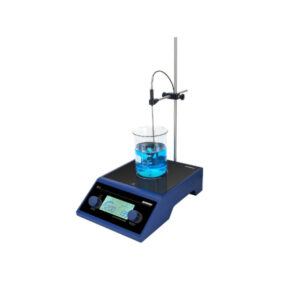

The rotary evaporator STRIKE 380 combines excellent operating characteristics and high performance levels, all in an ergonomic design. STRIKE 380 has been projected in complete respect of safety needs and in compliance with the existing directive regarding equipment construction and electromagnetic compatibility.

DESIGN – Compact and modern. All controls are placed on the central column to guarantee user-friendly and handly use.

CONTROL PANEL– The touch screen is wide and easy to read. The microprocessor is multi-programmable and GLP compliant.

POWERED GLASSWARE – Compact and modern. All controls are placed on the central column to guarantee user-friendly and handy use.

INTEGRATED VACUUM CONTROLLER – The optional vacuum controller is managed by the touch screen display that comes as standard

SEALING SYSTEM – The exclusive STEROGLASS sealing system allows a perfect vacuum-tight anti-corrosion seal without gaskets or other materials that can be damaged by solvent contact. This sealing system is a standard feature in all strike models and can be used with all types of glassware.

ROTARY EVAPORATOR INNOVATIONS – The following are the technical innovations applied to the construction of the STRIKE 380 Rotary Evaporator making it a fast, working, efficient, safe and maintenance free instrument.

FLASK ASSEMBLY – System used to assemble the evaporation flask. The evaporation flask is screwed onto the steam passing pipe to ensure easy assembly and dismounting operations as well as a perfect seal. (You may also use conventional unthreaded cone flasks and spring-clamps to mount the flasks).

SAFETY SHIELD – The shield is standard for all models. It can be removed by the operator and fitted beside the instrument.

STANDARD FEATURES AND PERFORMANCE:

- Removable safety shield

- Glassware lifting made possible with or without protective shield

- Maintenance-free PTFE and carbon graphite seals

- Powered glassware lifting equipment with safety release (in case of power failure)

- 3,5″ monochromatic LCD touch screen

- Quick Start/Stop control and parameter selector

- Rodavis evaporation ask connection system

- Removable thermostatic bath, PTFE coated

- GLP-compliant instrument (with USB interface)

- Optional fume temperature probe

- Optional vacuum controller

- Rotation speed from 20 to 280 rpm (150W induction motor)

- Thermostatic bath ambient temperature: 185℃ (2 possible settings: water and oil)

- Bath heater: 1200W

- Bath capacity: 5 liters

- Bath material: PTFE coated

- Removable bath for emptying

- Models available with vertical or slanting, standard or plastic-coated glassware

- Evaporating asks: 1000ml (optional 50 to 2000ml)

- Collecting asks 1000ml: (optional 250 to 2000ml)

- Overall dimensions: 690x700x430mm (vertical version)

- Weight:26,5 Kg (vertical version)

- Overall dimensions: 690x790x430mm (slanting version)

- Weight:26 Kg (slanting version)

- Voltage: 230 V AC, 50Hz

- Power consumption: 1400W

CONTROL PANEL AND MICROPROCESSOR:

- 3.5″ LCD graphic display touch screen (320 x 240 pixel)

- START/STOP control and quick basic parameter selection

- Real-time display of all basic operating parameters (bath temperature, rotation speed), vacuum level and fume temperature (if optional probe and vacuum controller are present)

- Real-time display of working method

- Method saving and retrieving (up to 10 methods)

- Timer

- Possibility to operate according to fume temperature (if optional probe is present)

- Possibility to create manual and automatic ramps according to time, by differentiating all working parameters (if vacuum controller is present)

- Possibility to download working method to PC through USB port and retrieve it at any time

- USB updatable multi-language software.

Specifications

| Technical data | Strike 380 |

| Models | Models available with slanting glassware, vertical glassware (steam sinking and steam rising type) |

| Glassware | Standard or plastic-coated glassware |

| Rotation speed | 20 to 280 rpm (150W induction motor) |

| Screen | 3.5″ monochromatic LCD touch screen |

| sealing | Maintenance-free PTFE and carbon graphite seals |

| Connection | Rodavis evaporation flask connection system |

| Bath temperature | 180℃ (2 possible settings: water and oil) |

| Bath heater | 1400W |

| Bath capacity | 5 liters |

| Temperature Stability | ±0.2℃ |

| Bath material | PTFE coated |

| Bath movement distance | 90mm |

| Draining | Removable bath for emptying |

| Stroke displacement | 13cm, adjusted, and can be stop at any position |

| Head angle adjustable | 0~15° |

| Cooling surface | 1500cm2 |

| Evaporating flasks | 1000ml (optional 50 to 2000ml) |

| Collecting flasks | 1000ml (optional 250 to 2000ml) |

| Weight | 26,5 Kg (vertical version), 26 Kg (slanting version) |

| Overall dimensions | 690x700x430mm (vertical version,HxDxL)

690x790x430mm (slanting version,HxDxL) |

| Voltage | 230 V AC, 50/60Hz |

| Options | Steam temperature probe, vacuum controller |

| protective shield | Glassware lifting made possible with or without protective shield |

| Other features | Powered glassware lifting equipment with safety release (in case of power failure)

Quick Start/Stop control and parameter selector |