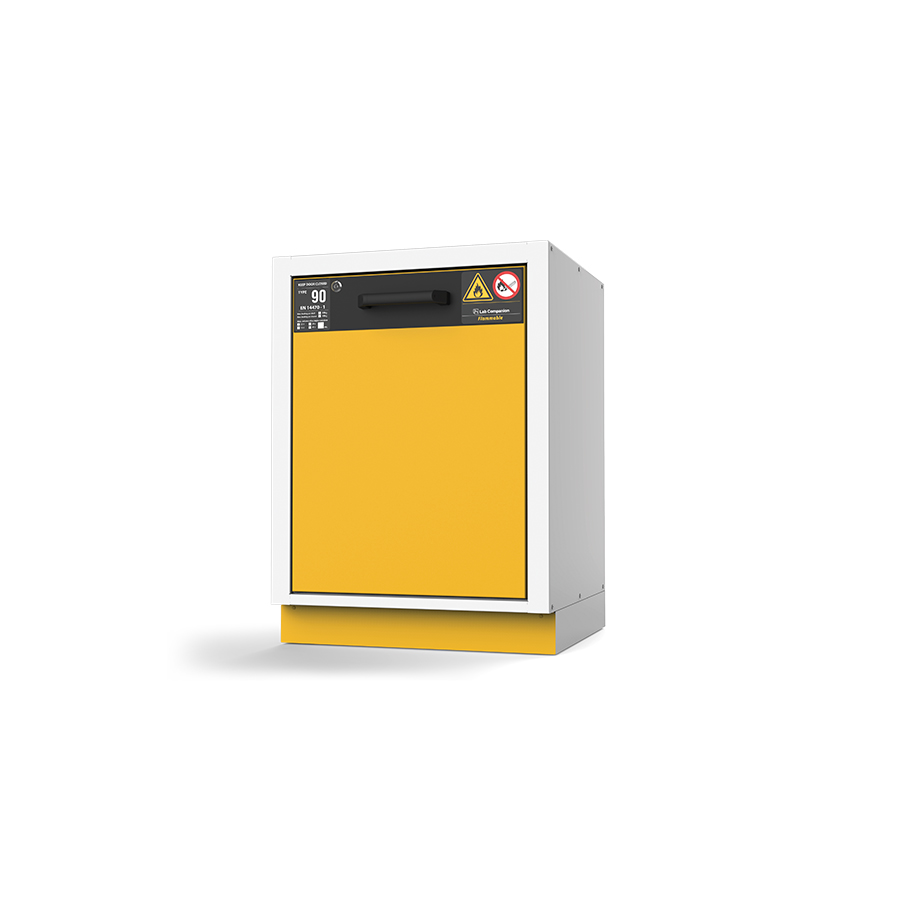

Safe storage from fire

- High fire resistance

Fire resistance performance is in accordance with the strictest European standard, with the internal temperature kept below 180K for up to 90 minutes in the event of fire. - Fire Response Sealing System

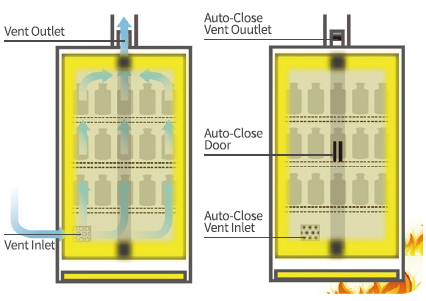

When the temperature reaches 50°C, the door automatically closes. When the ambient temperature reaches 70±10°C, the exhaust holes and ventilation openings are automatically closed, totally blocking the flow of heat from the outside in the event of fire - The right model for the application can be selected

Possible to suppress fire at the natural ignition point of the dangerous goods being handled.

Model selected considering the prediction time, etc. - Chemical resistant interior material

Excellent chemical resistance even for long-term use with the interior material coated with polyphenol resin. - Under bench type height-adjustable (SC3 Under-type Model)

750 mm/820 mm height can be selected considering the work height when hood is installed at the bottom.

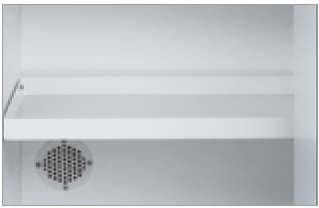

Solid and secure shelf structure

- Solid shelf structure

It is a solid structure allowing for up to 80kg to be held per shelf and it can be fixed firmly to the left and right inside walls - Safe shelf design

With 30mm-deep shelf shape for safe storage, it is designed to be safe even if the stored contents are leaked. - Right shelf selection

The built-in shelf is excellent in chemical resistance due to epoxy powder coating. Also, stainless steel shelves and PP trays can be selected (optional).

Proven fireproof performance!

Items Proven by Testing

- 30 minutes / 60 minutes / 90 minutes fire resistance performance test.

- For fire test according to standards of EN 1363-1, the time required for AT to be kept below 180°C is expressed as fire resistance (EN-14470-1).

|

|

|

|

|

Convenient Reagent In/Out Equipped with door closure to stop the door at the desired position for easy insertion and removal of flammable reagents.

|

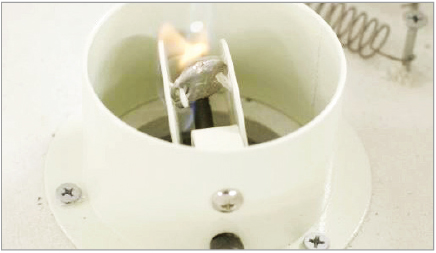

Automatically sealed ventilation

When the ambient temperature reaches 70±10°C in case of surrounding fire, the exhaust opening, and ventilation opening are designed to be automatically closed to completely prevent the inflow of external heat.

|

Triple insulation structure

All walls are constructed of the same triple-insulated structure and all gaps are treated with fire-retardant finishes to protect flammable materials in the event of a surrounding fire.

|

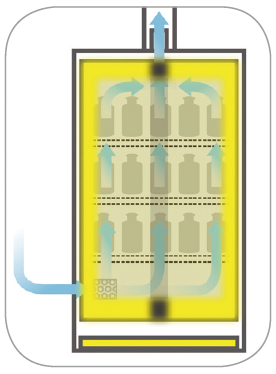

Safe ventilation of flammable vapor It is possible to discharge gas easily through the vent inlet and vent outlet to prevent accidents due to accumulation of flammable vapor, and to protect the health of the experimenter.

|

|

|

|

|

|

Configurable with lab safety workbench It is composed of a fume hood and a testing bench bottom, making it excellent for storing hazardous materials and waste liquids. |

Effluent reservoir

Safe handling in the event of stored material leakage and prevention of leakage out of the cabinets. |

Key lock device

Key lock is provided as standard to block unauthorized access. |

Safe stored materials handling

Ergonomic structure with easy access to shelves for user’s safety and convenience. |

|

|

||

|

Convenient moving and installation Forklift fork space for convenient movement. |

Extraction Module (option)

Filters flammable gas inside the cabinet with a carbon filter without connecting a separate duct. |

| EN 14470-1 | NFPA 30 | |

|---|---|---|

| Fire resistance performance |

0 | 0 |

| Fire test according to EN 1363-1, 15 min.- 90 min. (15 min. / 30 min. / 60 min. / 90 min.) |

NFPA 251 standard fire resistance test, 10 minute level | |

| Flammable vapor ventilation |

0 | 0 |

| Flammable vapor ventilation is recommended. Check sound pressure formation inside the cabinet during ventilation. |

Ventilation is not recommended. (Recommended to use level of container recommended in NFPA 30.) |

|

Keeps flammable vapors below the LEL concentration and removes odors through ventilation. |

It seals the ventilation holes, and an odor occurs inside the storage cabinet. |

|

| Safety Cover | 0 | 0 |

| Automatic door and ventilation closure during fire test | In the case of a fire test, test with the ventilation hole blocked. Fire safety not considered when connecting to external ventilation facilities. |

Comparison of EN 14470-1 and NFPA 30 International Standards

| Type | Model |

|---|---|

| Stand | SC3-30F-1912D2-C |

| SC3-30F-1906D1-C | |

| Under | SC3-30F-0812D2D-C |

| SC3-30F-0806D1D-C |

※ LC Connected service scheduled for release

Specification (Type 30)

| Model | SC3-30F-1912D2-C | SC3-30F-1906D1-C | SC3-30F-0812D2D-C | SC3-30F-0806D1D-C |

|---|---|---|---|---|

| Internal volume (L / cu ft) | 802 / 28.3 | 375 / 13.2 | 252 / 8.9 | 116 / 4.1 |

| Interior dimensions (W x D x H, mm / inch) |

968 x 507 x 1635 / 38.1 x 20.0 x 64.4 |

453 x 507 x 1635 / 17.8 x 20.0 x 64.4 |

506 x 415 x 602 * 2ea / 19.9 x 16.3 x 23.7 * 2ea |

468 x 415 x 602 / 18.4 x 16.3 x 23.7 |

| Exterior dimensions (W x D x H, mm / inch) |

1101 x 630 x 1951 / 43.3 x 24.8 x 76.8 |

586 x 630 x 1951 / 23.1 x 24.8 x 76.8 |

0.5 / 0.91200 x 560 x 820 / 47.2 x 22.0 x 32.3 |

600 x 560 x 820 / 23.6 x 22.0 x 32.3 |

| Quantity of shelf (standard / max.) | 3/5 | 3/5 | – | – |

| Max. load per shelf (kg / lbs) | 80 / 176.4 | 80 / 176.4 | 40*2ea 1) / 88.2*2ea | 40 1) / 88.2 |

| CE certification | O | O | O | O |

| Weight (kg / lbs) | 330 / 727.5 | 220 / 485.0 | 200 / 440.9 | 120 / 264.6 |

| Cat. No. | AAAF330470 | AAAF330440 | AAAF330430 | AAAF330420 |

| Product appearance |  |

|

|

|

| Product interior |

|

|

|

|

- Drawer Type is the maximum load for the Drawer.

- Providing epoxy powder coated bottom collecting sump set (standard), change to stainless steel material. (option)

Bottom Collecting Pump Specification by Model

| Model | Description (W x D x H, mm / inch) |

|---|---|

| SC-EF-1912D2 | 1194 x 484 x 92 / 47.0 x 19.1 x 3.6 |

| SC-EF-1906D1 | 594 x 484 x 92 / 23.4 x19.1 x 3.6 |

※ Choose one between a epoxy powder coated steel and a stainless steel steel material

Shelf |

Bottom Collecting Sump |

Tray (PP) |

Drawer |

Fume Extraction Module (EM-33) |

Plinth (side) +EM-33 |